Hotline:0769-89182111

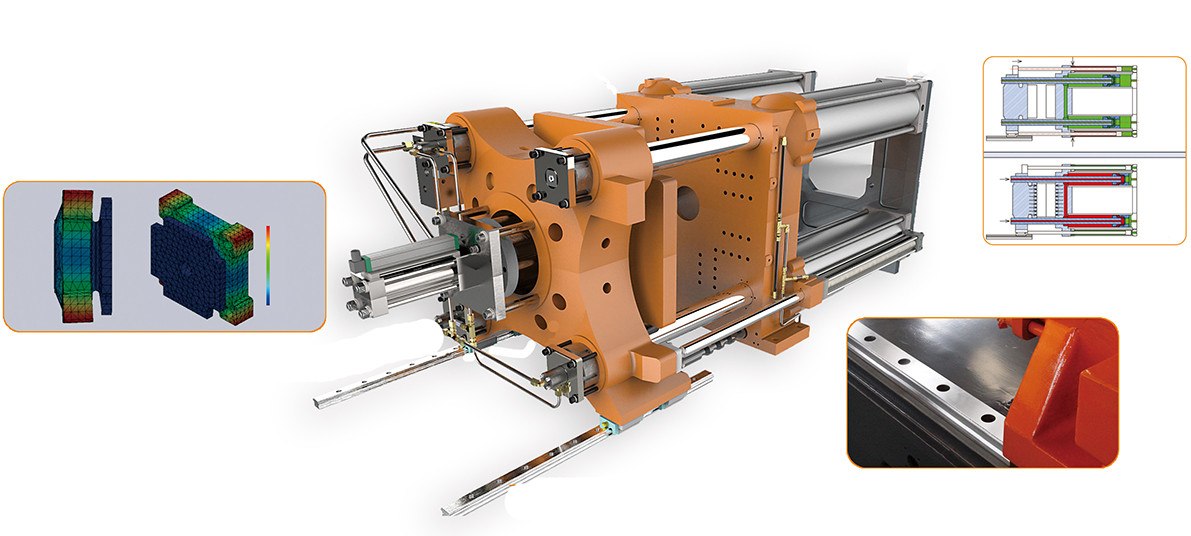

Core technology—clamping unit

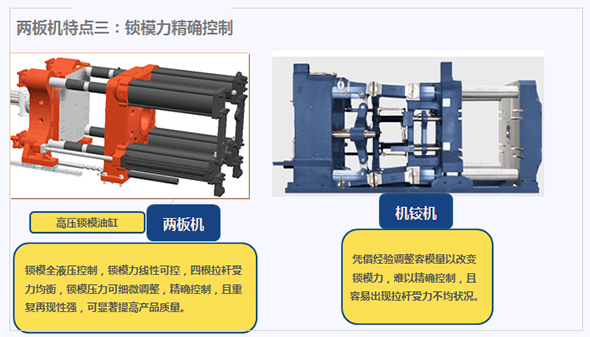

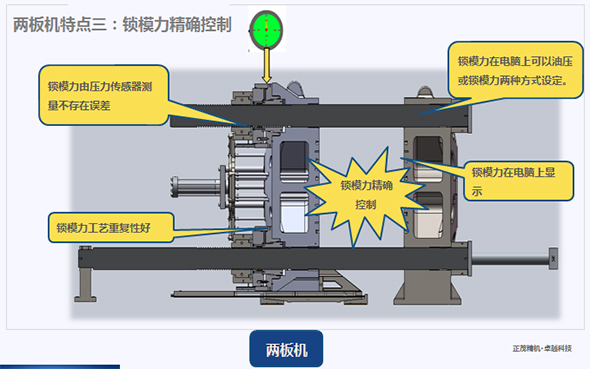

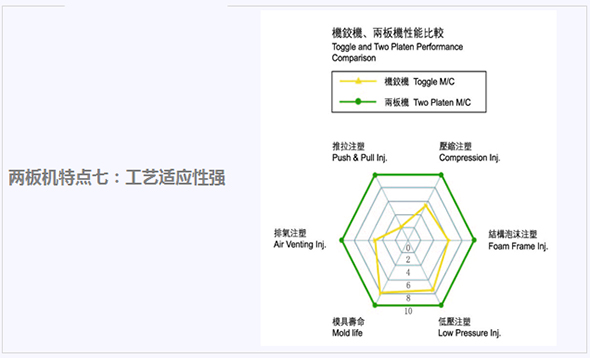

A.Efficient internal circulation oil circuit: this zero leakage circuit can boost pressure extremely quick and will sustain clamping force stable for a long time. The four cylinders are connected each other through the internal circuit built in stationary platen. Uniform clamping force, low resistance motion, high accuracy, fast speed and low power cost are available. Shock-free opening, best low and high pressure mold protection feature will give the mold longevity. Injection-compression molding process can be adopted as an option.

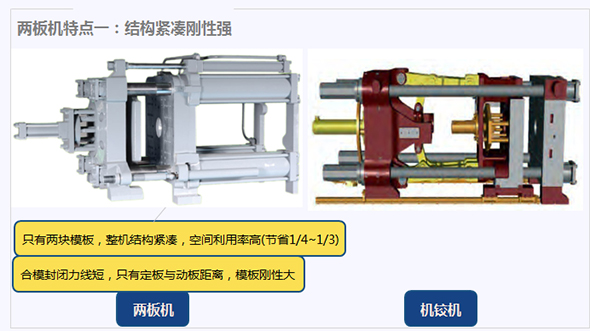

B.Compact two platen direct clamping structure: only two platens are required without rear platen and mold adjust device.

Fewer and light weight motion parts with small inertance create quick action with high precision.

Super long traveling length of the mold can molding deep cavity product.

The clamping cylinders are fixed on the stationary platen so the machine dimension can be shorted for making a better benefit within a smaller occupation area in the workshop.

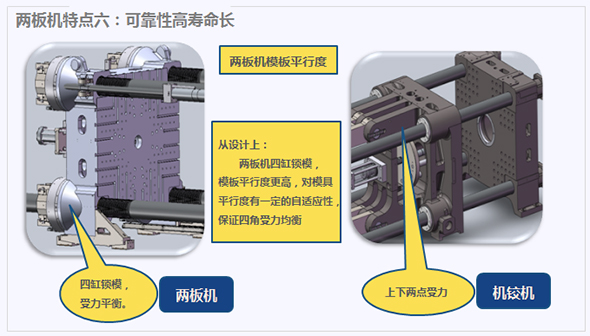

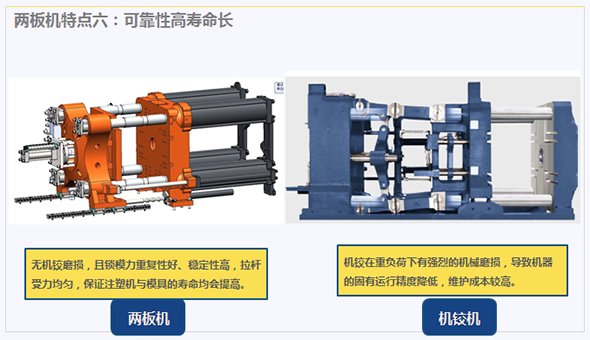

C.Composite platen stressed uniformly

Finite element method is adopted to optimize the composite platen design. The clamping force at the four corners of the platen is concentrated to the central area of the platen, and then is distributed homogeneously on the mold mounting surface. The mounting surface deformation is reduced to minimum, so the load on the mold will be more uniform, abrasion on the motion parts decreased to the lowest. Flash can be eliminated and the perfect uniform for the multi-cavities production can be performed.

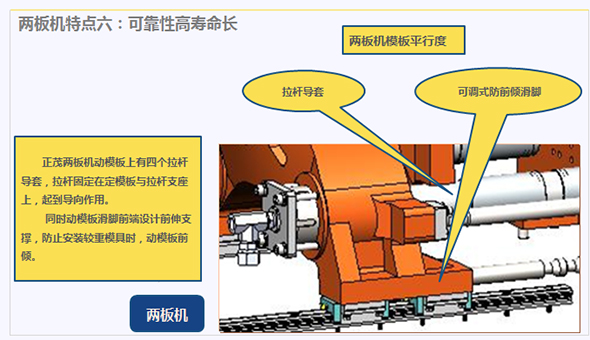

D.Precise linear guide rail supports the movable platen

This ideal supporting way has a high precision with low resistance.

Lubricant leakage free, no contamination occurred.

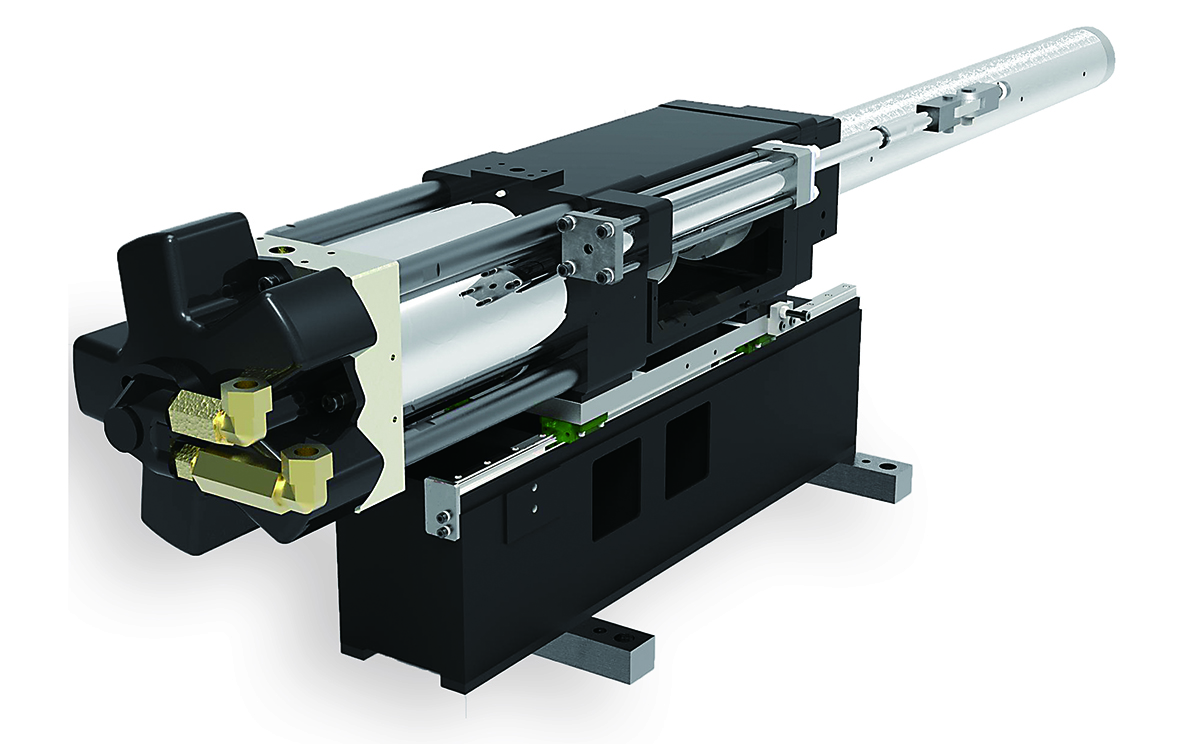

Core technology—injection unit

A.Single cylinder injection structure, Bloomachine is the first successful user in China

Suitable for high speed and super speed precise injection molding

Swiveling injection stand is easy to demount and purge the screw

Thin wall product with better repeatability can be molded

The injection components can move co-axially under a balance state

The injection components has small mass and low inertance

High control precision, low resistance and power cost

B.Precise twin cylinder injection structure

Compact structure, injection action guided by linear guide rail, high precision and complete modular design.

Single cylinder injection units can be interchanged each other as well as the screw.

Telephone:0769-89182111

Fax:0769-38921054

Mailbox:bmsales@bloomachine.Com